Planet TV Studios Exposes the Blueprint for Better Health: Blue Line Sterilization Unleashed!

Debuting Imminently on Bloomberg TV: Unveiling Progress in Healthcare & Sanitation Presented by Planet TV Studios, Frontrunners in Groundbreaking Television Production.

NOVATO, CALIFORNIA, UNITED STATES, January 3, 2024 ReportWire.org - Planet TV Studios, a top-tier producer of advanced television series, presents their upcoming healthcare documentary series titled "New Frontiers," showcasing Blue Line Sterilization Services, a leading California-based medical device sterilization company.

"New Frontiers" is a compelling series produced to showcase groundbreaking healthcare organizations that are on the cutting edge of revolutionizing the future of health management in the nation. The documentary episodes will premiere early January 2024 on national television, Bloomberg TV, and on-demand on-demand through numerous platforms, including Amazon, Google Play, Roku, and others.

Planet TV Studios is proud to have Gina Grad return as their host. Gina is an renowned author, podcast host, and radio personality based in Los Angeles, California. She previously performed as the co-host and news anchor of the Adam Carolla Show, a podcast that attained the Guinness World Record for the most downloaded episodes. Gina has also anchored KFI 640 AM and anchored mornings on 100.3 FM. Besides her broadcasting career, she is the author of "My Extra Mom," a children's book intended to help kids and stepparents in navigating the challenges of blended families.

Originating in 2009, Blue Line Sterilization Services has been devoted to reducing the time to market for innovators innovating new medical devices. The company is unique by maintaining a bank of 8 cubic foot ethylene oxide (EO) sterilizers, providing FDA and EU compliant sterilization with turnaround times between 1 to 3 days—an achievement impractical with larger EO sterilization services.

Co-founders Brant and Jane Gard observed the essential need for accelerated sterilization options, particularly for quickly evolving development programs producing innovative medical devices. The ability to swiftly navigate through device iterations is imperative in reducing the need for additional funding, preserving the value of investors' equity, and expediting time to market. Faster service and reduced time to market hold great value for employees, investors, and the patients benefiting from improved medical care.

Besides routine sterilization, Blue Line offers rapid turnkey validations and small batch releases that support clinical trials and FDA/CE submissions. Collaborating with Blue Line enables developers of new medical devices to notably shorten their schedules, speedily assess new design iterations, and expedite product launches.

Blue Line Sterilization Services continues to be committed to maintaining the highest standards of quality while consistently providing reliable, rapid, and responsive ethylene oxide sterilization and consulting services tailored to meet the unique needs of their clients.

About Planet TV Studios:

Planet TV Studios creates revolutionary, fact-based television series that offer insightful updates on the key industry, health-related, and social responsibility topics currently emerging in areas integral to our lives.

For more information about Blue Line Sterilization Services, refer to https://bluelineeto.com/.

For further information about the series, kindly visit https://planettvstudios.com / https://planettvstudios.com/backstage or reach out to Christian Alain Kelch at 888-210-4292 x100 or email christian@planettvstudios.com.

Medical Device Sterilization: Providing Patient Health and Alignment in Health Services

Daily, multitudes of medical devices—from rudimentary surgical instruments to high-tech implants—are used in health centers globally. While patients hardly ever dwell about the purity of these devices, the thorough process of medical device sterilization functions between ideal patient outcomes and potentially disastrous infections. Appreciating sterilization is critical not simply for medical professionals but for patients and the general public additionally. This all-encompassing guide examines in-depth into the world of medical device sterilization, investigating why it matters, the technologies behind it, regulatory considerations, and emerging trends shaping the future.

Critical Role of Medical Device Sterilization

Managing infections remains a key element of modern medicine. The Centers for Disease Control and Prevention (CDC) estimate that around 1 in 31 hospital patients experiences at least one healthcare-associated infection (HAI). Adequate sterilization of medical devices drastically reduces the risk of these infections, safeguarding patients and healthcare providers equally. Improper sterilization can prompt outbreaks of life-threatening diseases like hepatitis, HIV, and antibiotic-resistant bacterial infections.

Procedures for Medical Device Sterilization

The science behind sterilization has advanced significantly over the last century, utilizing a variety of methods suited to various types of devices and materials. Some of the most popularly adopted techniques include:

Steam Autoclaving

Autoclaving remains the most widespread and trusted method of sterilization, particularly suitable for surgical instruments and reusable metal devices. Using high-pressure saturated steam at temperatures around 121–134°C, autoclaving effectively kills bacteria, viruses, fungi, and spores. This method is swift, cost-effective, and ecologically sound, although not suitable for heat-sensitive materials.

Modern Movements in Medical Instrument Sterilization

As the field matures, several key trends are driving sterilization processes:

Eco-Friendly Sterilization Techniques

As environmental policies strengthen, companies are rapidly investing in green sterilization processes. Strategies include limiting navigate to this website reliance on dangerous chemicals like ethylene oxide, exploring environmentally safe packaging materials, and optimizing electricity use in sterilization techniques.

Innovative Materials and Device Complexity

The proliferation of innovative medical devices—such as robotic surgery instruments and intricate diagnostic equipment—demands sterilization methods capable of handling sensitive materials. Evolution in sterilization include methods including low-temperature plasma sterilization and hydrogen peroxide vapor, which can sterilize without damaging vulnerable components.

Digital Traceability and Verification

With advances in digital technology, tracking of sterilization procedures is now more precise than ever. Digital traceability systems offer in-depth documentation, automated compliance checks, and real-time updates, significantly cutting down human error and raising patient safety.

Patient Safety and Ethical Commitments

Medical device manufacturers, sterilization providers, and healthcare facilities share an critical responsibility to protect patient safety. Adherence to patient safety is paramount, shaping decision-making, and practices must always comply with stringent standards to secure community trust.

In Summary

Medical device sterilization demonstrates the intersection of healthcare innovation, patient safety, and regulatory compliance. As medical technology continues to evolve, sterilization practices must respond continuously, reinforcing the paramount commitment to quality care and shaping public trust in medical treatment itself.

Blue Line Sterilization Services: Reshaping Healthcare through Dedicated EO Sterilization

Conceived on a clear mission serve the carefully targeted demands of medical device sterilization, Blue Line Sterilization Services (BLSS) has reshaped how medical innovations find their way to patients throughout the world. By centering uniquely on ethylene oxide (EO or EtO) sterilization in small batch processing, BLSS has solidified a crucial role in the healthcare industry, enabling groundbreaking medical devices to enter the market in a shorter timeframe, more securely, and with advanced predictability than has ever been possible.

Expert Approach: Small Scale EO Sterilization

In a medical domain where quick turnaround can greatly affect patient outcomes, Blue Line Sterilization Services has earned recognition through its precise approach to small load sterilization. Their thoughtful focus on smaller, precisely controlled sterilization cycles empowers medical device companies—particularly active in rapid development, clinical trials, and niche markets—to introduce life-changing innovations to market quickly and productively.

Located in Novato, California, BLSS manages specialized sterilization chambers specifically constructed to manage smaller batches, which are essential during early-stage product testing, clinical trial production, and validation phases. These cutting-edge chambers allow for the precise application of sterilization processes, providing an fundamental resource for manufacturers working through complex regulatory landscapes.

Full-Spectrum Client-Centric Sterilization Solutions for Healthcare Innovations

Recognizing the vital importance and significant role of sterilization during product development, BLSS grants comprehensive, total sterilization solutions, consisting of:

Holistic Validation Programs: Entire validation methods crafted to adhere to the exacting demands of both the FDA and ISO standards, securing products steadily meet required sterility assurance levels.

Sterilization Resistance Comparison: Vital for refining sterilization practices, BLSS’s comparative resistance testing allows for heightened sterilization outcomes.

Exceptional Project Management: With a specialized team, BLSS handles the sterilization process end-to-end, enabling businesses to commit fully on their core business objectives activities.

Streamlined Pathway: BLSS expedites the shift from early-stage development to clinical testing and commercialization, enabling prompt market deployment.

Dedication to Quality: Mastery in Regulatory Adherence

BLSS continues unwavering to rigor. Their strict adherence to ISO 13485 and FDA rules guarantees every sterilization cycle satisfies the most stringent industry standards. Through persistent refinement efforts and strict quality assurance protocols, BLSS consistently outshines both client expectations and regulatory benchmarks.

Revolutionizing Medical Innovation: How BLSS is Changing the World

Blue Line Sterilization Services is actively changing the landscape of medical innovation. By providing prompt and optimized sterilization solutions, BLSS enables medical device manufacturers to significantly accelerate product development timelines. This optimization directly contributes into improved patient outcomes, as lifesaving technologies reach clinics more swiftly.

Furthermore, BLSS’s quick prototyping and clinical trial support enable medical device companies to swiftly iterate and refine their designs. Companies capitalize on faster product development cycles, swiftly bringing groundbreaking devices to market and significantly enhancing healthcare outcomes worldwide.

Impacting Patient Care: The Power of Innovation

Every healthcare product processed by Blue Line Sterilization Services represents a potential breakthrough in patient care. Devices varying from novel surgical tools to life-changing implants are subject to thorough sterilization procedures, confirming patient safety. BLSS’s efficient implementation of expedited and trustworthy sterilization protocols positively affects the success rate of clinical interventions, dramatically improving patient recovery times, reducing complications, and increasing healthcare outcomes.

Empowering Device Market Access

The rapid, reliable sterilization capabilities from BLSS enable medical device manufacturers, from manufacturers of pioneering surgical equipment to producers of life-enhancing implants, to accelerate their development timelines, bringing life-saving healthcare solutions to market swiftly and efficiently.

Shaping Industry Best Practices

BLSS’s innovative approaches have significantly influenced industry standards and best practices. Their refined, smaller-scale EO sterilization processes have raised industry awareness check my blog about the merits and necessity of tailored sterilization services. Consequently, other sterilization providers have begun recognizing and integrating these specific sterilization methods, subsequently refining overall industry performance.

Moreover, BLSS’s strong advocacy for rapid prototyping and streamlined clinical trials facilitates medical device iteration. This capability allows companies to efficiently adapt and refine their products, reducing development cycles, responding faster to clinical needs, and thus guiding to safer, more successful patient care globally.

Forging Trust Through Dependability: Expertise and Excellence

Recognizing BLSS’s extraordinary reputation, medical device companies consistently rely on Blue Line Sterilization Services due to their unwavering commitment to immediacy, integrity, and top-tier service quality. Client testimonials continuously highlight BLSS’s ability to build strong partnerships, positioning the company as a crucial ally for medical device manufacturers. Their peerless reputation for reliability allows manufacturers to plan confidently, certain that their sterilization needs will be capably managed.

Strategic Collaborations and Industry Recognition

Blue Line Sterilization Services widens its influence through strategic collaborations with prominent industry organizations and leading medical device firms. These partnerships significantly enhance BLSS’s potential and broaden their industry impact, driving further advancements in medical sterilization technology. BLSS’s significant contributions have been validated by industry peers and regulatory authorities through various awards and recognitions, reinforcing their Check This Out status as a recognized industry leader.

Concluding Observations: A Permanent Mark on Medical Advancements

Blue Line Sterilization Services stands at the forefront of medical innovation, dramatically reshaping how medical devices reach patients globally. Their specialized sterilization processes dramatically reduce the time-to-market for revolutionary healthcare technologies, directly optimizing patient outcomes and enabling healthcare providers to deliver safer, more effective treatments.

As the medical industry continues to expand, demand for specialized sterilization providers such as Blue Line Sterilization Services will inevitably increase. Their unwavering dedication to quality, responsiveness, and innovation positions them as an vital part of healthcare’s future, continually enabling transformative medical advancements that elevate patient care and lives around the world.

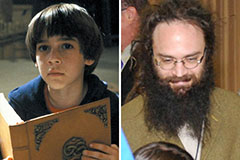

Barret Oliver Then & Now!

Barret Oliver Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!